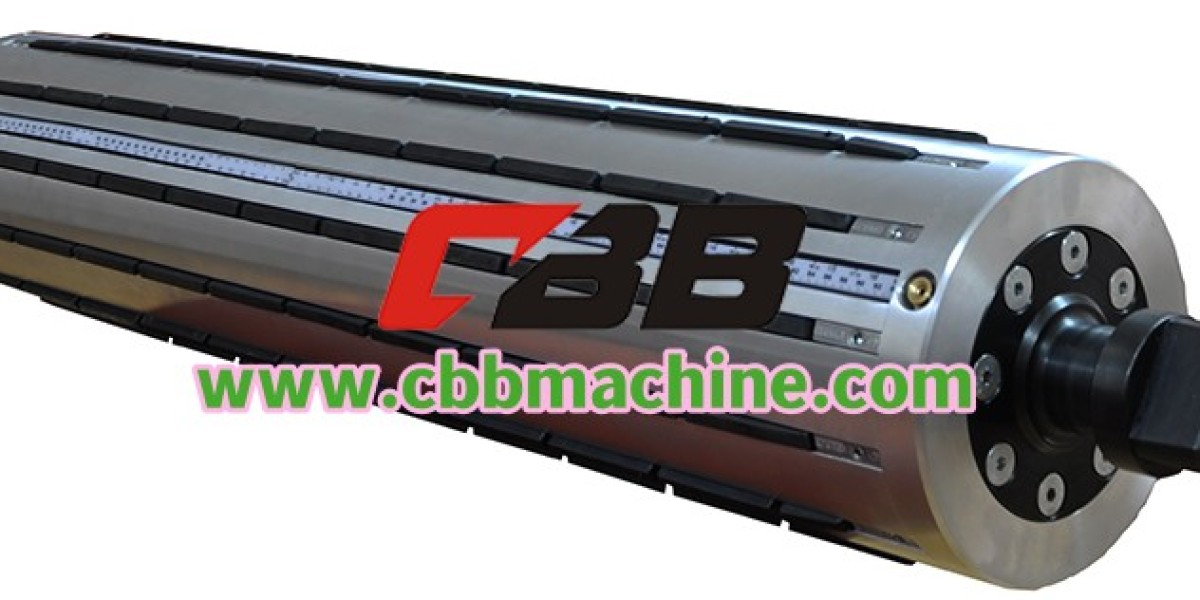

In many industrial processes, the Pneumatic Expanding Shaft serves as a practical tool for secure roll handling, especially when incorporated into machinery produced by Cbbmachine. Its expanding mechanism allows materials to be gripped with measured pressure, supporting workflows centered on steady engagement and controlled transitions across varied production conditions.

A defining quality of this shaft is its calm, predictable expansion. When pressurized, it distributes force evenly, allowing the core to sit firmly without abrupt tightening. This balanced interaction helps maintain alignment as rolls accelerate, decelerate, or shift through different material stages. By offering controlled stability, the component nurtures a smoother operational rhythm where operators can rely on consistent behavior rather than sudden changes.

Ease of handling further strengthens its practicality. The inflation and deflation steps are intentionally straightforward, enabling quick roll changes and simplified adjustments. This measured simplicity supports production teams who require dependable transitions without complex mechanisms interrupting their pace. Every shift becomes more manageable, shaping a work environment guided by clarity and steady progression.

Durability also plays an important part in its value. Designed to withstand repeated cycles of expansion and release, the shaft maintains integrity while supporting internal forces produced during winding and unwinding tasks. Its balanced form helps reduce strain on surrounding components, encouraging long-term coordination across broader machinery arrangements. Over repeated use, its subtle reliability becomes a quiet but meaningful strength.

Versatility adds another dimension. The shaft adapts to varied material types, differing core specifications, and diverse processing lines, including printing, laminating, coating, and packaging applications. Its ability to fit into multiple contexts without demanding redesign allows facilities to maintain flexibility while preserving operational consistency. The component blends into systems that appreciate steady function rather than disruptive adjustment.

As production environments evolve toward refined coordination, tools built on measured response become increasingly important. A device that expands with controlled intent aligns well with workflows that prioritize order, predictable movement, and thoughtful engineering. Its influence may be subtle, but it shapes the tone of entire processes by reinforcing balance during each stage of operation.

If you are drawn to equipment defined by clarity and quiet precision, consider following a path that leads to deeper insight. Visit https://www.cbbmachine.com/product/ , and let your next click open a space where refined mechanical ideas wait to be observed at your own pace.