Dry break coupling is extensively utilised throughout Australia in industries that require secure, efficient, and spill-unfastened switch of unsafe or sensitive drinks and gases. Designed to minimise environmental impact and place of work dangers, this mechanism permits operators to disconnect hoses or pipelines with minimum fluid loss. Its use has accelerated as Australian regulatory requirements an increasing number of emphasise containment, employee safety, and operational reliability.

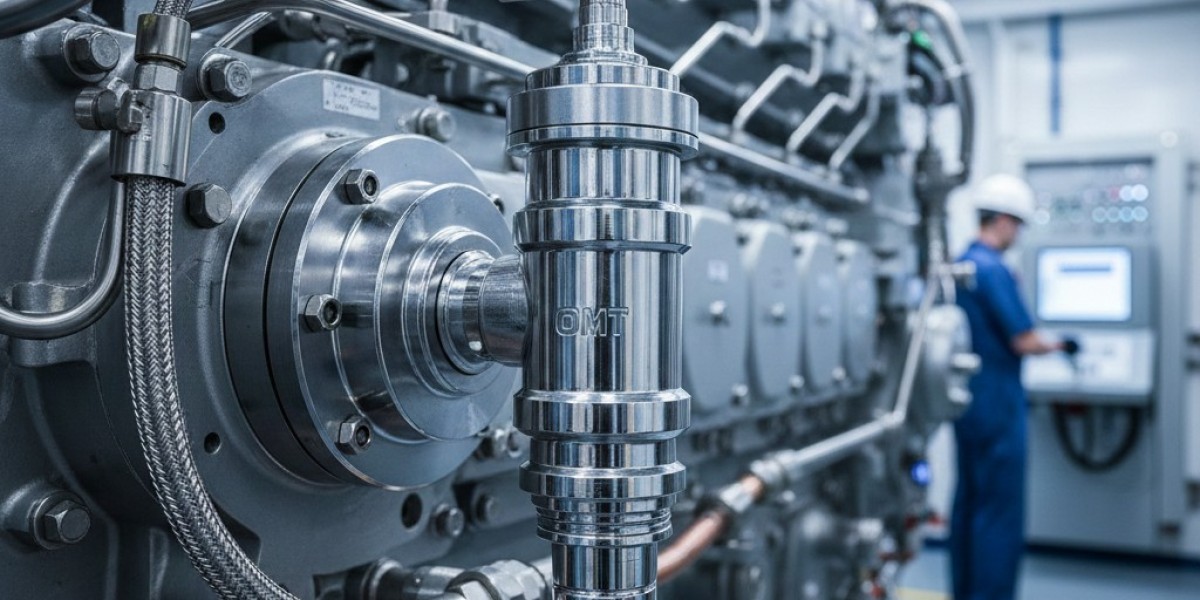

A dry ruin coupling usually includes two major additives—a hose unit and a tank unit—that routinely seal upon disconnection. This sealing action prevents unintended discharge, making the machine treasured in sectors inclusive of fuel distribution, chemical processing, agriculture, mining, and marine services. In Australia, where remote operations and cruel environments are not unusual, the coupling’s sturdiness and leak-prevention features make contributions to more managed dealing with procedures.

Fluid transfer web sites regularly contain excessive pressures, corrosive materials, or common connection cycles. Dry smash coupling systems assist lessen infection, protect device, and support compliance with environmental hints, which might be mainly stringent round Australian waterways and protected ecosystems. Their capacity to restrict vapour release also aligns with national desires to reduce emissions and guide cleanser operational practices.

Different configurations of dry destroy coupling are used relying on the medium, connection length, and required flow charge. Operators in Australia pick options primarily based on temperature tolerance, fabric compatibility, and the extent of automation needed. These structures are engineered for quick engagement, decreasing downtime in the course of loading or unloading approaches. In sectors inclusive of delivery and logistics, this contributes to smoother scheduling and improved operational efficiency.

Overall, dry destroy coupling performs a tremendous function across Australian industries via selling safer transfer strategies, reducing environmental risks, and assisting regulatory compliance. Its adoption keeps to grow as industries seek dependable answers that prioritise spill prevention and administrative center protection.